Sunshine Rolls Out Aluminum Box Cars

Sunshine Rolls Out Aluminum Box Cars

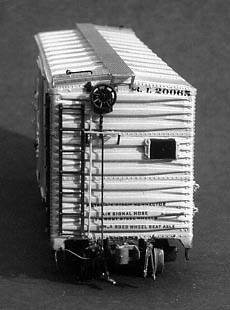

Aluminum box cars for the RI, M&St.L, Alton, C&O and NKP are the latest HO scale cast resin kits released by Sunshine Models. Their roof, sides and ends were unpainted and duplicated the polished aluminum sheeting used on WW II aircraft. The kits sell for from $33 to $34.

In the last year of World War II, flush with a massive capacity to prodice aluminum sheet, the aluminum producers began a campaign to gain acceptance of this metal in freight car construction. Box cars, gondolas and hoppers were built with aluminum alloys to prove the metal's mettle (sorry, capability) and test the cars on the nation's railroads. The box cars were the most visible examples of these efforts.

The economics of aluminum construction never satisfied the railroads. While the weight savings were undisputed, the costs of non-standard construction remained high. Steel, like aluminum, was in plentiful supply and was competitive in price. No car manufacturer championed the new material, collectively remaining committed to all-steel construction.

The problem of corrosion between dissimilar metal parts would prve the undoing of the aluminum box cars. By the early 1960s, the aluminum box cars began to show signs of corrosion at the junctions where the aluminum met the few steel members. While a caulking compound was used to separate steel and aluminum, it only exacerbated the problem. This phenomenon was caused by an electrical current flow between the two metals. Caulking served to accenctuate, or increase, the current, intensifying the corrosion at those points.

The Mt.Vernon Car Co., in conjunction with Reynolds Aluminum, built ten cars each for the Rock Island, Minneapolios and St. Louis and Alton in 1945. These cars followed the Modified 1937 AAR design with a 10'6" IH. The significant difference from the steel cars was the use of seven narrow panels on either side of the door with more numerous underlying vertical posts. The cars also used a non-standard Dreadnaught end with a 3/3/4 corrugation arrangement.

In November of 1947, the Chesapeak & Ohio and Nickel Plate constructed ten aluminum cars each. These cars were built to the 10'0" IH Postwar AAR design with 3/4 Improved Dreadnaught ends.

The Rock Island purchase was for head end mail express cars. The ten cars, numbers 20060-20069, had black stenciling on the aluminum sides, passenger steam and signal lines, Youngstown corrugated doors and cast side frame trucks. The underbody was black. The journal box lids were painted aluminum. The lettering was immediately modified to include 'Express' on the lower left side, as was common on other Rock Island green express box cars. These cars were later equipped with trucks with roller bearings. They remianed in service into the early 1970s.

The M&St.L cars were for LCL or merchandise service. No steam or signal lines were included, but the journal box lids of the cast side frame trucks were painted aluminum. The underbody was painted black. Doors were Youngstown's corrugated. The cars were placed in thr series 1000-1018, even numbers only. The stenciling on the cars was green. In 1956, all ten cars were still in service.

The Alton's ten cars, 1200-1209, were built for mail-expresss service. The yreceived the steam and signal lines necessary for passenger operations. They came with Superior doors and the same cast side frame trucks as on the RI cars. The cars received the standard Alton lettering of the era including the Alton cirlce/trianlge herald, all stenciling including the herald and the hardware were red. The underbody was coated with black car cement and the journal box lids were painted aluminum. After the GM&O-Alton merger took place in May, 1947, the cars were slowly relettered GM&O, but remained in the same number series. 'Gulf Mobile & Ohio' in seven inch high letters on a single line along the lower right hand side replaced the Alton herald. Lettering remained red. In 1956, all ten GM&O cars were still in operation.

The C&O cars were built at the company's Russell, KY shops in late 1947, along with five aluminum hoppers. The stenciling and underbody were both black and ARA cast sideframe trucks were used. The cars were placed in the 2900-2909 series. The cars served for many years and nine were still in service in 1965. The C&O's cars were employed in freight service only.

The ten Nickel Plate cars, 8500-8509, were constructed at the Frankfort, IN shops for head end service. The side sheets, doors, running boards, brake carlines, floor stringers and even the hand brake housing were all made of aluminum alloy. The cars were painted vlack below the side sill and were stenciled in black including special instructions for handling. The cars rode on ASF A-3 Ride Control trucks and were equipped with steam and signal lines for passenger service. The weight savings over comparable steel cars was 8,000 pounds per car. These cars were eventually placed into general freight service.

All blocks of cars received Apex Tri-Lok running boards, AB brakes and Ajax power hand brakes.

The Sunshine Models aluminum box car kits should be finished with Testor's Buffing Aluminum paint to duplicate the reflective surface of aircraft aluminum.

Castings are vacuum-formed gray urethane. Etched stainless steel running boards are included, as well as steam and signal lines and marker light brackets for the head end cars. All parts except trucks and couplers are provided. A four page Prototype Data Sheet and four pages of instructions with in-process photos are included.

The head end cars - RI, Alton and NKP - sell for $34 each and the freight car versions sell for $33 each.

For a more detailed discussion of the history, full description of the kits and an order form, send an SASE to Sunshine Models.

Kits are available directly from Sunshine Models, Box 4997, Springfield, MO 65808. Shipping is $4 for one to five kits in the US. Missouri residents add 6.60% sales tax.